China Wholesale COIL WIRE NAIL Manufacturer,supplier | delaitehardware

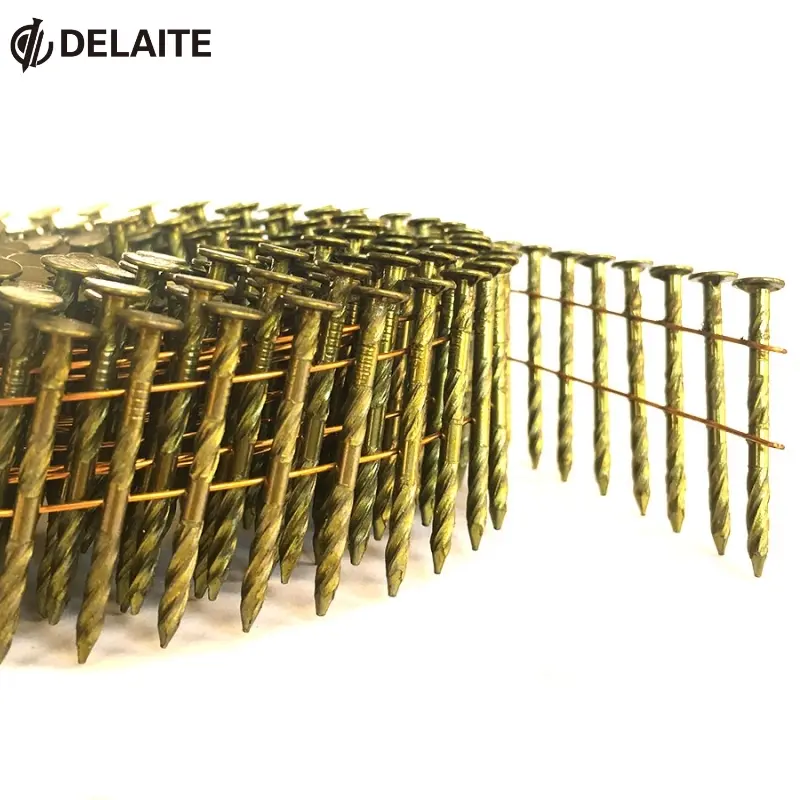

Coil Nails Features

1. corrosion resistance

2. security thick

3. uniform cap size

4. screw thread clear

5. high quality wire rod

6. bending and rust resistance

Coil Nails Specifications

|

Specification

|

PCS*coils/box

|

N. W. (kg)

|

Box/20GP

|

Box/40GP

|

||

|

mm

|

Inch

|

|||||

|

2.1*25

|

1''

|

0.083''

|

400*40

|

11.25

|

1900

|

2300

|

|

2.1*30

|

1.18''

|

400*40

|

13.51

|

1600

|

1920

|

|

|

2.1*32

|

1.26''

|

400*40

|

14.41

|

1500

|

1800

|

|

|

2.1*35

|

1.38''

|

400*40

|

15.76

|

1400

|

1650

|

|

|

2.1*38

|

1.5''

|

400*40

|

17.11

|

1300

|

1500

|

|

|

2.1*40

|

1.57''

|

400*40

|

18

|

1200

|

1440

|

|

|

2.1*42

|

1.65''

|

400*40

|

18.91

|

1200

|

1370

|

|

|

2.1*45

|

1.77''

|

400*40

|

20.26

|

1100

|

1280

|

|

|

2.1*50

|

2''

|

400*40

|

22.26

|

1000

|

1170

|

|

|

2.3*38

|

1.5''

|

0.090''

|

300*40

|

15.39

|

1430

|

1650

|

|

2.3*40

|

1.57''

|

300*40

|

16.2

|

1430

|

1600

|

|

|

2.3*45

|

1.77''

|

300*30

|

13.67

|

1650

|

1900

|

|

|

2.3*50

|

2''

|

300*30

|

15.19

|

1540

|

1700

|

|

|

2.3*57

|

2.25''

|

300*30

|

17.31

|

1180

|

1500

|

|

|

2.5*45

|

1.77''

|

0.099''

|

300*30

|

16.15

|

1500

|

1600

|

|

2.5*50

|

2''

|

300*30

|

17.94

|

1400

|

1450

|

|

|

2.5*55

|

2.17''

|

300*30

|

19.74

|

1100

|

1300

|

|

|

2.5*57

|

2.25''

|

300*30

|

20.46

|

1200

|

1250

|

|

|

2.5*60

|

2.36''

|

300*30

|

21.53

|

1100

|

1200

|

|

|

2.5*65

|

2.56''

|

300*30

|

23.33

|

1100

|

1100

|

|

|

2.5*70

|

2.76''

|

300*20

|

16.75

|

1500

|

1550

|

|

|

2.5*75

|

2.95''

|

300*20

|

17.94

|

1400

|

1450

|

|

|

2.8*75

|

2.95''

|

0.110''

|

225*20

|

16.88

|

1540

|

1540

|

|

2.8*80

|

3.15''

|

225*20

|

18

|

1430

|

1440

|

|

|

2.8*90

|

3.54''

|

225*20

|

20.26

|

1210

|

1280

|

|

|

3.1*100

|

3.94''

|

0.122''

|

225*10

|

13.8

|

1911

|

1880

|

|

3.8*130

|

5.12''

|

0.15''

|

150*10

|

17.96

|

1456

|

1450

|

Shank Type

The main types of coil nail include smooth shank coil nails, ring shank coil nails, and screw shank coil nails.

• Smooth Shank: Smooth shank nails are the most common and are often used for framing and general construction applications. They offer enough holding power for most everyday use.

• Ring Shank: Ring shank nails offer superior holding power over smooth shank nails because the wood fills in the crevasse of the rings and also provide friction to help prevent the nail from backing out over time. A ring shank nail is often used in softer types of wood where splitting is not an issue.

• Screw Shank: A screw shank nail is generally used in hard woods to prevent the wood from splitting while the fastener is being driven. The fastener spins while being driven (like a screw) which creates a tight groove that makes the fastener less likely to back out.

Surface Treatment

Painting coated coil nail is coated with a layer of paint to help protect the steel from corroding. Although painted fasteners will corrode over time as the coating wears, they are generally good for the lifetime of the application. Areas near the coasts where the salt content in rain water is much higher, should consider Stainless Steel fasteners as salt accelerates the deterioration of the galvanization and will accelerate corrosion.

General Applications of Coil Nails

Coil nails are mostly used for wooden pallet, box building, wood framing, sub floor, roof decking, decking, fencing, sheathing, Fence Boards, Wood Siding, Exterior House Trim. They are used with nail guns.